- OMCI RIG TECHNICAL & SUPPORT SERVICES PVT. LTD.

Criticality of safe and reliable “Lifting gears” for handling and shifting of material on board all off-shore assets is well understood. Cranes, as the most convenient and efficient means of handling such operations, has been the preferred choice amongst all such Lifting / Handling equipment.

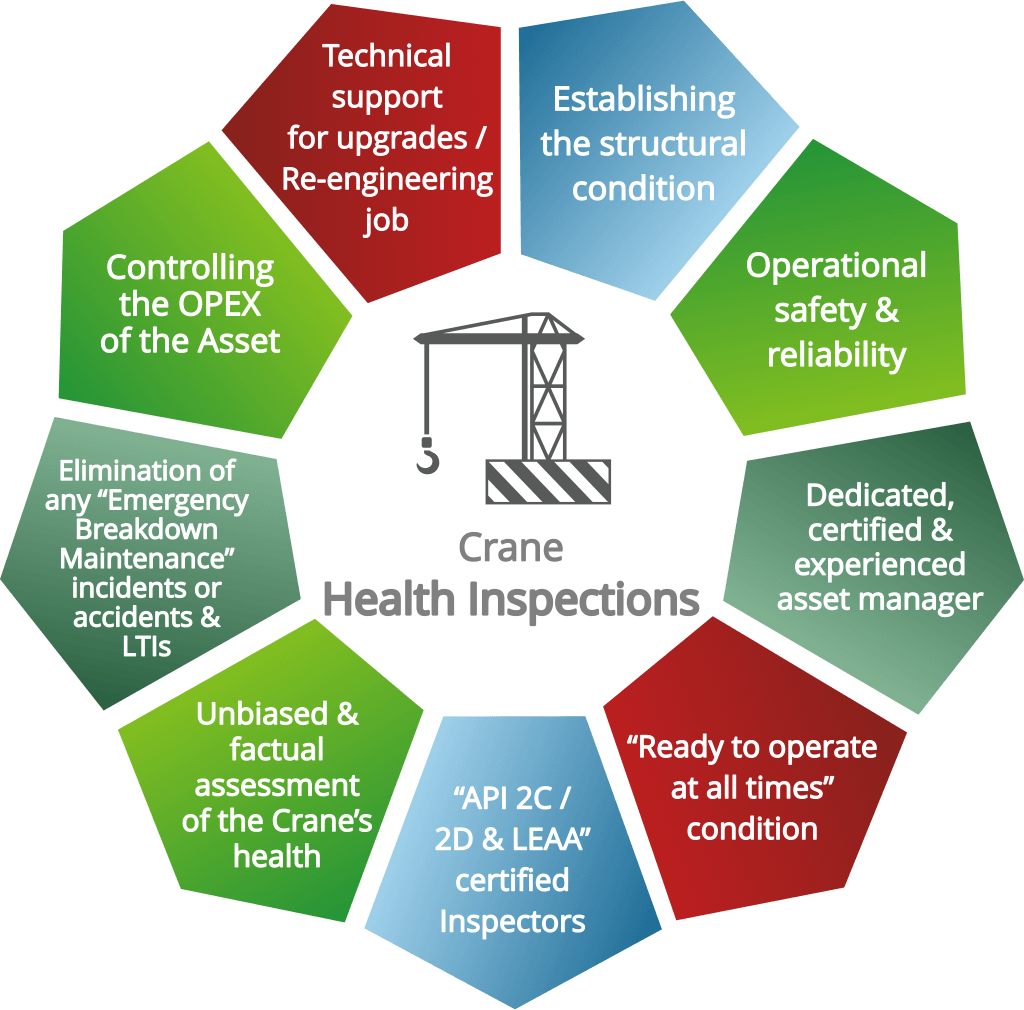

There have been numerous methodologies adopted by Asset Owners / Operators to ensure that the cranes on-board their Offshore Asset is maintained, inspected and operated optimally. However, all conventional methods adopted to establish a Crane’s condition have been limited to only “Assessing its structural integrity”, without any attention to other relevant aspects of the Equipment.

We, at OMCI, understand that just establishing the structural condition of a critical equipment like the Crane is only half-the-job done. Operational safety and reliability is equally dependent on the sub-components, systems and controls that finally determine the performance and reliability of the Cranes. A malfunctioning “Counter-balance Valve” or a “Solenoid Valve” (depending on the Crane type) can result in as serious an incident as the failure of the weld seam along the load path.

OMCI has developed a “Technical Management System” for the Cranes, where a dedicated, certified and experienced Asset Manager is responsible to inspect and maintain each Crane (Asset) in “Ready to operate at all times” condition, minimizing delays / downtime due to non-availability of cranes. With an experienced pool of specialists from diverse backgrounds (Marine / Offshore / Ship-building / Mechanical, etc.), we undertake detailed health assessment of all aspects of a Crane (mechanical, electrical, hydraulic, life cycle evaluation etc.) by certified “API 2C / 2D & LEAA” Inspectors.

Our reports provide an unbiased and factual assessment of the Crane’s health (both structural & operational), thereby enabling the Asset Owner to plan maintenance / upgrades in an informed and phased manner. This eliminates any “Emergency Breakdown maintenance”, incidents or accidents and LTIs (with consequential un-budgeted high expenses) and helps in controlling the OPEX of the Asset Owner / Manager – a critical requirement in today’s market scenario. Our periodical inspections ensure that the Cranes are maintained and “ready to operate condition at all times”. Technical support for Upgrades/ Re-engineering jobs and Comprehensive equipment maker/supplier data base enable us to locate spares from the latest to even the most antiquated equipment, ensuring that the equipment functions optimally, in accordance with its designed criteria.

New regulations for Environmental Safety are being formulated on an accelerated basis. Ratification of the KYOTO protocol and introduction of the MLC (Maritime Labour Convention) has mandated that type of equipment and the life of personnel on board offshore assets is regulated to achieve minimum standards. Life of the equipment on board is dependent on the ambient operating conditions, more so in the case of electronic equipment which require a regimented temperature environment to perform optimally. Quality of life of personnel (and hence their productivity) can be enhanced by maintaining the working environment in a “comfort zone”.

OMCI’s proactive, round the year Maintenance Support service (AMC) facilitates the Client to ensure the optimized condition of the HVAC system is achieved. Our robust environment policy guides us to help our Client in drawing the road map of much acclaimed “Zero” Ozone Depletion Potential (ODP) target.

With a team of Marine-cum-reefer engineers with 40 years of pool experience in operating and maintaining the HVAC systems, we have devised an “Intelligent Maintenance” methodology to ensure maximum operational efficiency of the systems. Our experts undertake a detailed Survey of the equipment / system to establish the factual condition of the equipment and then recommend “Modifications / Up-gradation / Maintenance” Proposals in the report

We undertake customized service requirements (such as System efficiency upgrades) to comply with recent global obligatory/recommendatory regulations for environmental compliance, Routine Health assessment for condition-based maintenance program for AMCs and Ventilation & Provision Refrigeration inspection and Maintenance Support services.